PRODUNT

Magnesium alloy CP

Aluminum alloy CP

Zinc alloy CP

Reference electrode

Test Stub

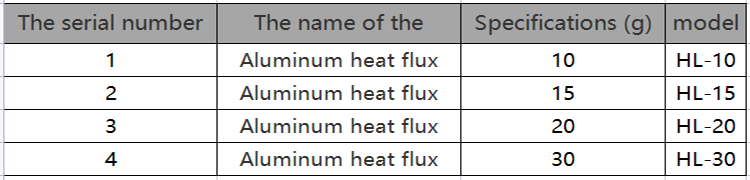

Thermite flux

Power impressed anode

Auxiliary materials

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

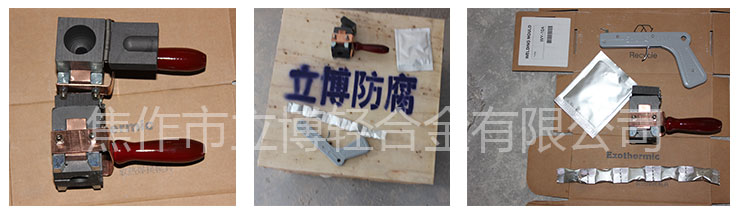

thermite welding kit

Type:Auxiliary materials

Features:The welding process simple operation, does not require an external power source and heat source, and the welding of low cost, stable and reliable quality, very suitable for field welding operation of cable and other metal components, this manual involves the product is suitable for the cathodic protection system installation in the process of copper core cable and connection of steel structure welding or copper cable.

Release DATE:2021-06-18

Thermite welding is the use of metal oxide and metal aluminum exothermic reaction between the superheated molten metal to heat the metal to achieve the method of bonding.Thermic welding began in the late 19th century, when H. Goldschmidt found that the exothermic reaction between aluminum powder and metal oxide could be initiated by an external heat source, and once the reaction could be self-sustainable. The general formula for this reaction is:

Metal oxide + aluminum (powder) → alumina + metal + heat

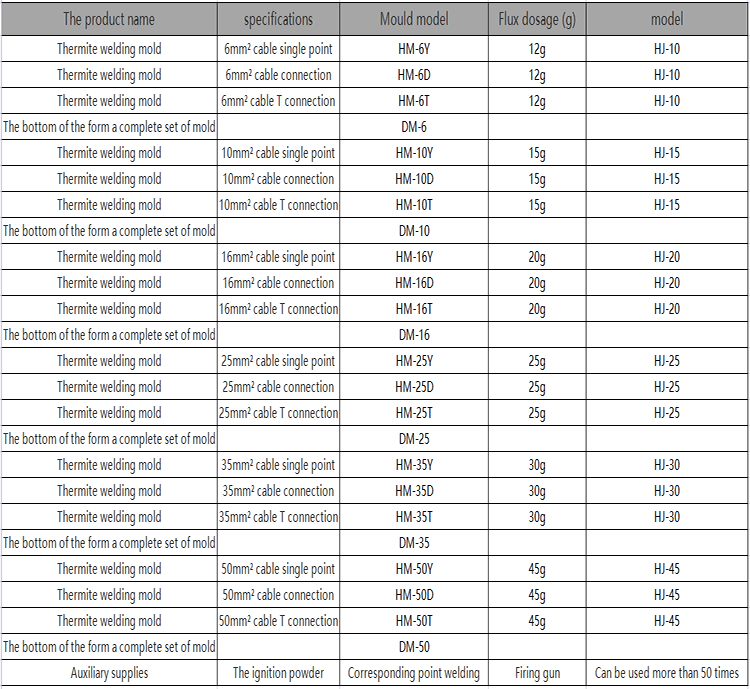

Thermal-aluminium fusion welding can mainly weld pure copper, brass, bronze, copper, copper clad steel, pure iron, stainless steel, wrought iron, galvanized steel, cast iron, etc.

Product type: thermite welding kit

Use of welding die: used for welding flux and wire to steel pipe tools.

Product specifications: can be welded 6 square, 10 square, 16 square, 25 square and other specifications of the cable. Edge protection.

Thermite welding kit:

Thermite welding is a method of combining metals by heating the superheated molten metal produced by the exothermic reaction between metal oxide and metal aluminum.

The welding process simple operation, does not require an external power source and heat source, and the welding of low cost, stable and reliable quality, very suitable for field welding operation of cable and other metal components, this manual involves the product is suitable for the cathodic protection system installation in the process of copper core cable and connection of steel structure welding or copper cable.

Aluminium heat welding

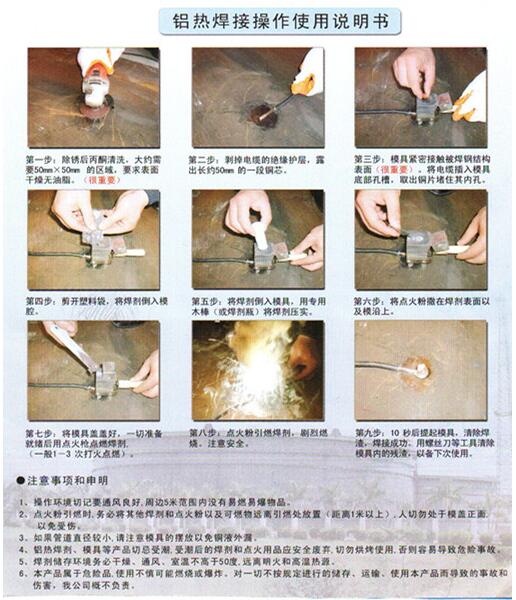

Thermite welding process introduction:

Thermite welding is the use of metal oxide and metal aluminum exothermic reaction between the superheated molten metal to heat the metal to achieve the method of bonding.

Thermic welding began in the late 19th century, when H. Goldschmidt found that the exothermic reaction between aluminum powder and metal oxide could be initiated by an external heat source, and once the reaction could be self-sustainable. The general formula for this reaction is:

Metal oxide + aluminum (powder) → alumina + metal + heat

Thermal-aluminium fusion welding can mainly weld pure copper, brass, bronze, copper, copper clad steel, pure iron, stainless steel, wrought iron, galvanized steel, cast iron, etc.

The characteristics and advantages of thermite welding:

The current closure of the welding point is equal to that of the wire;

The solder joint is permanent and will not cause high resistance due to loosening or corrosion.

The solder joints resemble copper but are stronger than copper itself and are not affected by corrosive products;

The solder joints can withstand repeated large surge current (fault) without degradation;

The welding operation method is simple and easy to use.

The equipment is light and easy to carry;

When welding, no external power or heat source is needed;

The quality of welding can be verified from the appearance;

Can be used for welding copper, copper alloy, copper plated steel, all kinds of alloy steel including stainless steel and high resistance heating heat source material.

The main points of thermite welding process:

1. Factors affecting welding effect

The surface of a good solder joint is full and bright, without pores and slag. After cutting, its section becomes a whole without pores and defects. The most important reason that affects the welding effect is moisture or water vapor. Because the mold, welding powder and the welded object may absorb water, how to prevent or remove water vapor is the most important step that must be taken during welding.

Another factor that affects the welding effect is the cleanliness of the mold and the welded object. For example, the dust, grease, oxide or other attachments on the surface of the welded object must be removed to make it clean and bright before welding operation can be carried out. Otherwise, the electrical conductivity and mechanical properties of the welded joint will be affected. If the residue left in the mold is not completely removed, it will cause the solder joint surface is not smooth, not bright.

To sum up. Points to note: 1, remove water and gas (can be baked with blowtorch), 2, clean the welding, 3, clean mold

2. Matters needing attention when applying welding powder

(1) Each package of welding powder corresponds to a solder joint, and the welding powder brand number should correspond to the mold, which should be carefully checked and confirmed before use.

(2) Multi-layer protection has been taken for the welding powder when it leaves the factory, but it is recommended to keep it properly to avoid moisture.

Preparation work before thermite welding connection is used:

Before each start, use a heating tool (blowtorch or drying box) to bake and dry the mold to remove water and gas.

Clean the mold after each use with a soft brush or other soft object to avoid damage to the mold.

Check the density of the contact surface of the mold to prevent the leakage of copper liquid from the gap during operation.

Die clamp is used for opening and closing die, the tightness of die clamp has an impact on the welding effect, please check the die clamp carefully before welding, and make appropriate adjustments.

The die is made of graphite, which is relatively fragile and cannot withstand the impact of throwing and strong force. Therefore, welding beyond the size of the die should not be forced into the die, or hard materials and tools should be used to remove the residue.

The service life of the mold is generally more than 50-100 times.

Thermite welding applications: thermite welding is suitable for cathodic protection, power, grounding, railway and other industries of the connection of conductors

Points for attention when using thermite flux mold:

The operating environment must be well ventilated, and there are no inflammable and explosive items within the perimeter of 5 meters.

When the ignition powder is ignited, be sure to place other flux, ignition powder and combustible materials away from the ignition place (the distance is more than 1 meter), and do not put people on the front of the mold cover to avoid injury.

If the pipe diameter is small, please pay attention to the placement of the mold to avoid leakage of liquid copper.

Preparation work before thermite welding connection is used:

Before each start, use a heating tool (blowtorch or drying box) to bake and dry the mold to remove water and gas.

Clean the mold after each use with a soft brush or other soft object to avoid damage to the mold.

Check the density of the contact surface of the mold to prevent the leakage of copper liquid from the gap during operation.

Die clamp is used for opening and closing die, the tightness of die clamp has an impact on the welding effect, please check the die clamp carefully before welding, and make appropriate adjustments.

The die is made of graphite, which is relatively fragile and cannot withstand the impact of throwing and strong force. Therefore, welding beyond the size of the die should not be forced into the die, or hard materials and tools should be used to remove the residue.

The service life of the mold is generally more than 50-100 times.

Thermite welding applications: thermite welding is suitable for cathodic protection, power, grounding, railway and other industries of the connection of conductors

Points for attention when using thermite flux mold:

The operating environment must be well ventilated, and there are no inflammable and explosive items within the perimeter of 5 meters.

When the ignition powder is ignited, be sure to place other flux, ignition powder and combustible materials away from the ignition place (the distance is more than 1 meter), and do not put people on the front of the mold cover to avoid injury.

If the pipe diameter is small, please pay attention to the placement of the mold to avoid leakage of liquid copper.

客服QQ

客服QQ